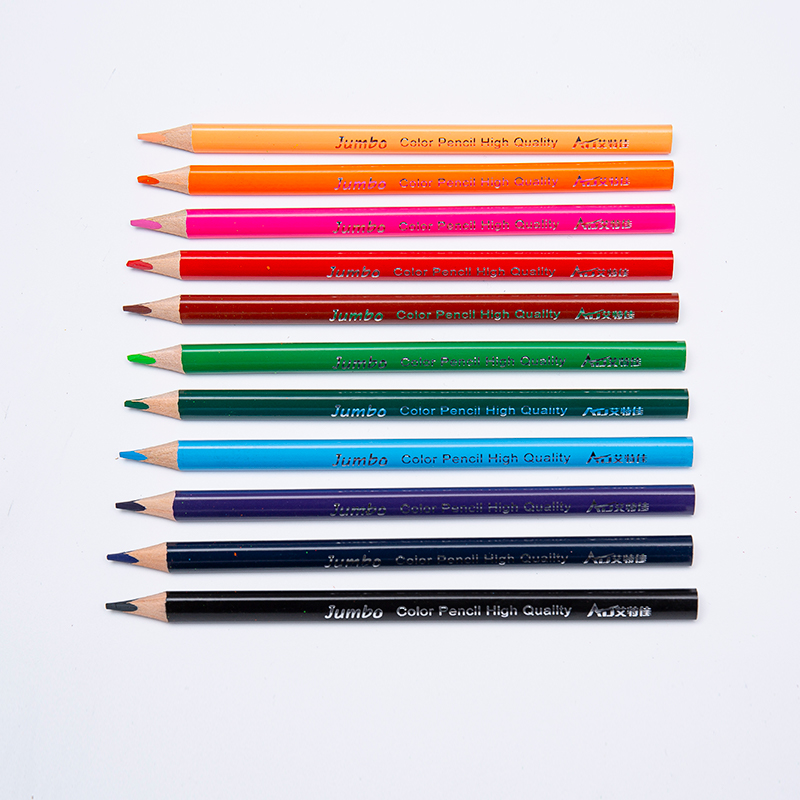

A pencil begins long before color is added or the core is inserted. For many brands in the colored pencil market, the quality of pencil slats determines how smooth production runs, how stable a pigment core sits, and how consistent the final product looks. When slats are uniform, dry, and clean, factories gain better control over shaping and assembly. When they are not, everything slows—coating lines need retouching, shaping machines jam, and pigment cores fracture during processing. This is why pencil slats and the support from skilled pencil slats manufacturers matter greatly for customers planning stable product lines.

Colored pencils use pigment mixed with wax or oil, sometimes designed to work with water. These materials respond differently to pressure and heat, which makes the wooden body especially important. A stable slate protects the core and supports clean sharpening for users ranging from students to professional illustrators.

1. Stable Material for Cleaner Assembly

Many customers face the same recurring issue: pigment cores breaking during assembly. This often happens when pencil slats vary in density or moisture. Stable pencil slats provide predictable pressure resistance, helping the colored core remain intact when glued and shaped.

Factories producing water-soluble or oil-based colored pencils benefit from consistent slats because these cores are usually softer than graphite. When the wood support is stable, the core stays in line and performs well during later sharpening and coloring.

2. Smooth Coating and Printing for Better Visual Impact

A colored pencil's appearance plays a large role in market acceptance, especially for art sets and school kits. Coating quality directly depends on how uniform the slat surface is. Pencil slats with clean surfaces allow coatings to spread evenly without patching or random absorption marks.

When printing brand logos or color names, a stable slat avoids small vibrations or surface irregularities that can distort the print. Distributors needing consistent packaging results often prioritize pencil slats manufacturers who maintain tight standards for surface finish.

3. Scalable Supply for Growing Product Lines

As colored pencil demand increases, brands need suppliers who can support varied product ranges. Reliable pencil slats help companies expand from small packs to larger assortments or mixed sets that combine graphite and colored pencils.

Predictable slats mean buyers can standardize their dimensions, coating formulas, and quality checks without repeating testing for every shipment. This supports smoother long-term planning and more stable cooperation between factories and global distributors.

4. Lower Waste During Cutting and Sharpening

One hidden cost in pencil production is waste created during slitting, shaping, and sharpening tests. Low-quality slats splinter more easily, creating extra dust and reducing usable volume. This becomes a daily challenge in busy factories working with pigment cores, which are more delicate than graphite.

High-quality pencil slats reduce tool wear and help keep sharpening tests consistent. A cleaner cut means fewer rejects and a smoother workflow for both small and high-volume production runs.

Across all stages—assembly, shaping, coating, and packaging—pencil slats influence how each colored pencil performs in a user's hand. Brands that value stable production and clean visual presentation often work with experienced pencil slats manufacturers who understand the demands of colored pencil cores. With reliable materials, production teams gain smoother lines, stronger bonding, and predictable results, helping them deliver colored pencils that feel responsive and enjoyable for artists, students, and hobbyists worldwide.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体