Pencil production looks simple from the outside, yet many distributors and brands know it depends heavily on one core material: pencil slats. When a slat is stable, clean, and uniform, everything downstream becomes easier—machining, shaping, slitting, bonding, painting, and packing. When it is inconsistent, every stage faces delays and additional costs. That is why buyers increasingly seek pencil slats manufacturers that understand production pressure, global timelines, and the challenges of modern writing-product markets.

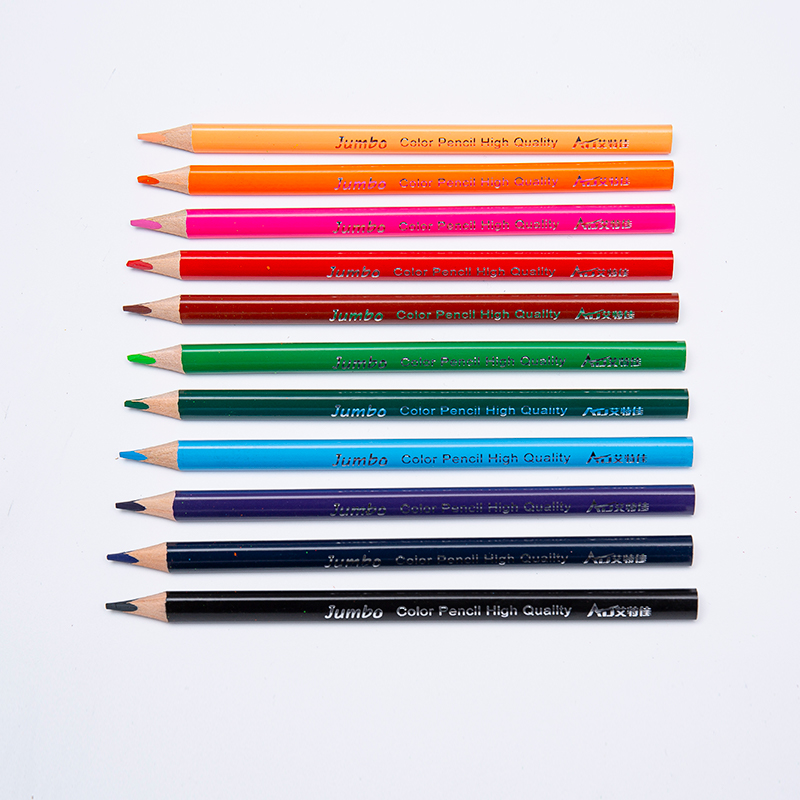

Zhejiang Aitejia Stationery Co., Ltd. has grown with this industry since 2004. With research, production, and sales integrated under one operation, the factory supports more than 30 pencil product types and an annual capacity of over 900 million units. The experience gained over these years shapes how we approach pencil slats and the needs of clients who depend on a stable supply.

1. Material Stability Reduces Grinding and Shaping Loss

Many buyers struggle with poor-quality slats that crack under pressure or chip during shaping. This slows down production lines and increases waste. Reliable pencil slats provide consistent density and moisture stability, allowing smoother machining across long shifts. A consistent feedstock helps factories keep output steady without constant adjustments.

For clients producing graphite pencils, colored pencils, or specialty lines, this stability keeps the process predictable. It also supports cleaner cutting edges, which helps the core sit in alignment through the gluing and shaping stages.

2. Surface Cleanliness Supports Smooth Coating

A common user pain point appears after assembly: coatings that streak, bubble, or absorb unevenly. This problem often traces back to the slat surface. When pencil slats are clean and uniform, the painting line runs more smoothly and gives a consistent visual effect.

Brands with higher design requirements depend heavily on reliable pencil slats manufacturers because decorative printing, dipping, or spraying needs consistent absorption. Without this, production teams spend more time correcting visual flaws, which affects delivery timelines and packaging plans.

3. Production Scalability Improves Long-Term Planning

Many distributors experience growth but struggle to scale because their suppliers cannot match volume needs. A manufacturer with unified R&D and production capability supports this growth more easily. Zhejiang Aitejia's integrated system was built for long-term stability, making larger seasonal or project-based orders easier to manage.

Reliable pencil slats help brands maintain product consistency across years. Clients don't need to adjust color formulas, sharpening tests, or outer packaging standards every time a new batch arrives. This reduces workload for QA teams and keeps product lines aligned with market expectations.

4. Global Buyers Value Predictable Cooperation

For many international customers, the challenge is not only product quality but also clear communication and stable scheduling. Pencil slats manufacturers with established systems help buyers coordinate cycle times, quality checks, and customization requirements with fewer interruptions.

Zhejiang Aitejia has supported global clients with unified solutions—from pencil slats to finished pencils—allowing brands to work with one stable partner rather than juggling multiple suppliers. This simplifies procurement and helps distributors maintain reliable delivery cycles.

Every pencil begins with a slat, and every brand that relies on large-scale writing products understands how much this base material affects cost and workflow. With consistent pencil slats and experienced pencil slats manufacturers behind the supply, production teams gain smoother processes and fewer unexpected adjustments. Zhejiang Aitejia continues to develop materials and expand capacity to support partners looking for long-term stability and dependable writing solutions.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体