An HB pencil is a versatile tool that plays an essential role in both writing and drawing. Its balanced hardness provides a medium that is neither too soft nor too hard, making it suitable for a wide range of applications. Whether used in schools, offices, or art studios, an HB pencil offers consistent performance and reliable line quality. Understanding the characteristics of the pencil and how it is produced can help businesses, educators, and professionals choose a supplier that delivers dependable products.

Features of an HB Pencil

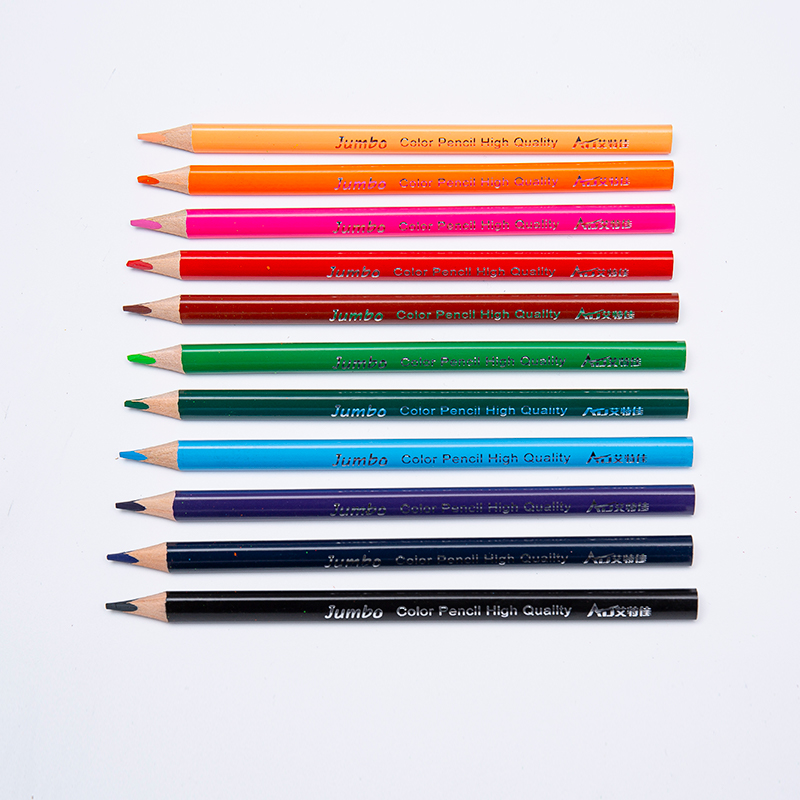

Hb pencils are graded to provide a balance between light and dark lines. The graphite core allows for smooth shading while maintaining precision for technical or detailed work. Softer pencils like B grades produce darker marks, whereas harder H grades produce lighter lines. Hb pencils fall in the middle, providing a versatile option suitable for general writing, sketching, and preliminary drawings.

The quality of the wood casing, graphite mixture, and manufacturing process all influence performance. A skilled HB pencil manufacturer carefully selects materials to produce consistent smoothness, reduce breakage, and deliver uniform lines. For bulk buyers or institutions, this consistency reduces waste and ensures pencils perform reliably in daily use.

Choosing the Right HB Pencil for Applications

Selecting the right HB pencil depends on the intended use. For note-taking and office work, a standard HB pencil offers readable, clean lines that are easy to erase. For sketching or preliminary artwork, it provides moderate shading ability without smudging excessively. Educational institutions often prefer HB pencils because they provide a balance between durability and usability for students of all ages.

B2B buyers, including schools, distributors, and office suppliers, need to consider quality, consistency, and supplier reliability. Manufacturers who provide detailed specifications and maintain strict quality control help ensure that bulk orders meet expected standards.

The Role of an Hb Pencil Manufacturer

An Hb pencil manufacturer oversees every step of production, from graphite mixing to barrel shaping and quality testing. The hardness of the cycle must be carefully controlled to deliver uniform performance across batches. Manufacturers may also innovate in wood selection, cycle smoothness, and break-resistance technology to meet evolving market demands.

For B2B clients, a reputable manufacturer guarantees consistent pencil quality, reducing complaints and returns. Transparency in production processes and clear communication about material quality help buyers make informed purchasing decisions. Some manufacturers even offer private-label options or custom packaging for educational and corporate clients.

Maintenance and Longevity of Hb Pencils

Maintaining an HHB pencil is straightforward but important. Proper storage in a dry environment, careful sharpening, and avoiding dropping the pencil can preserve the graphite core. Manufacturers often reinforce the cycle and improve casing durability to minimize breakage, which is especially valuable for schools and bulk buyers.

Reliable pencils save costs over time, providing a consistent user experience for students, professionals, and artists alike. Labeling the pencil with clear hardness and brand information also helps end-users select the right tool without confusion.

An HB pencil is a reliable, versatile tool suitable for writing, drawing, and sketching. Understanding its features, the role of the manufacturer, and proper handling can help businesses and professionals select pencils that perform consistently. A dependable Hb pencil manufacturer provides quality and reliability, supporting institutions and distributors with products that meet everyday needs and professional expectations.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体