A drawing pencil may look simple, but users across education, design, and art often search for something far more reliable than a basic tool. Many customers face common pain points: inconsistent hardness, breakable cores, uneven wooden barrels, or unstable supply chains. When a brand or distributor seeks factory partners, they want predictable quality that supports their users' daily tasks. Below is a look at how a drawing pencil and the production behind it bring value to real-world work.

1. Material Control Matters More Than People Think

Users often complain that a pencil grade marked “B” from one supplier feels like “HB” from another. This inconsistency disrupts shading, drafting accuracy, and classroom teaching. A drawing pencil factory with controlled graphite-clay ratios keeps the hardness range steady. This offers predictable strokes, whether used for layouts, sketchbooks, or detailed illustrations.

Harder grades produce fine, clean lines for diagrams or handwriting. Softer grades support rich tones and smooth shading for creative work. When these grades remain consistent from batch to batch, artists and schools don't need to adjust techniques for every shipment. Users simply get the feel they expect each time.

2. Durability and User Comfort Reduce Waste

Breakage is one of the many common complaints from students and hobby users. A well-made drawing pencil avoids brittle cores by using uniform graphite extrusion and proper wood bonding. That means fewer snapped tips, less sharpening, and reduced material waste during long sessions.

For wood selection, stable cedar or basswood allows clean sharpening without splintering. This creates a smoother daily experience, especially for classrooms or studios where hundreds of pencils may be used each week. A drawing pencil should feel good in the hand and behave predictably from the early line to the last millimeter of the core.

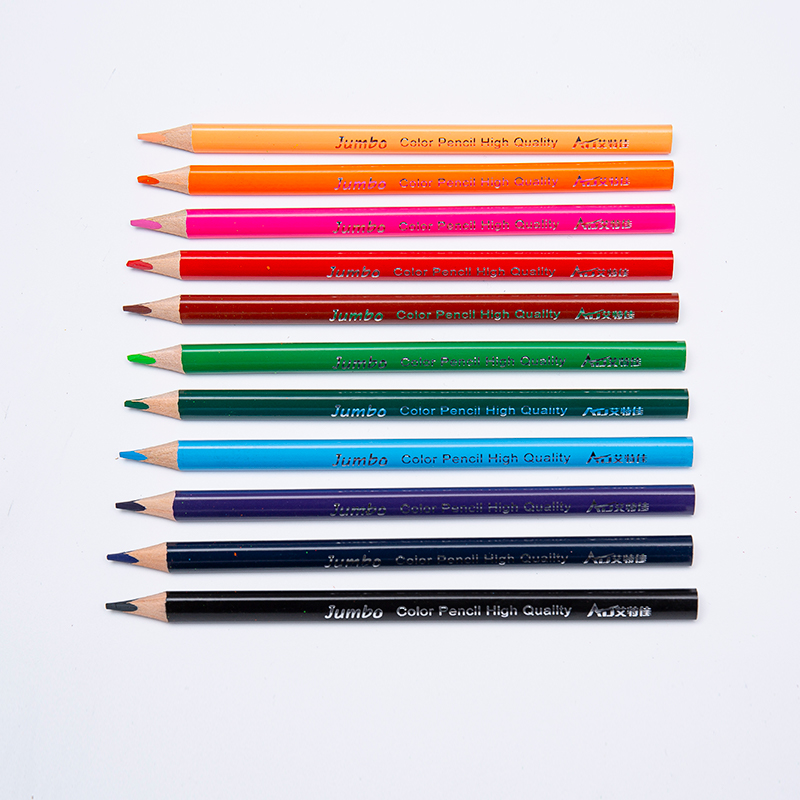

3. Expanding Creative Options With Colored Pencil Production

Many buyers today seek more than graphite. They want both graphite and colored solutions under one reliable partner. When a drawing pencil factory also manufactures colored pencils, this creates advantages for distributors: unified packaging, harmonized quality, and a stable mixed-product supply.

Colored pencils require different formulations—wax-based for smooth coverage, oil-based for crisp detail, and water-soluble types for flexible blends. Factories with experience in these materials help brands build broader product lines without changing suppliers. This is useful for art sets, school kits, and hobby markets where diversity of color and texture matters.

4. Supply Stability Shapes Buyer Confidence

A factory's production capacity directly influences how brands grow. Distributors often struggle with suppliers who cannot match seasonal demand or special bulk orders. A capable drawing pencil factory supports flexible volume, dependable cycle times, and clear communication.

A stable supply also protects users. A school system or design studio that adopts a certain drawing pencil needs continuity. Sudden changes in graphite feel or wood type disrupt long-term projects. Reliable factories help brands maintain the same experience across years of purchasing, which strengthens trust and repeat business.

Across different fields—from drafting tables to classrooms—people need tools that respond well to real work. A drawing pencil that delivers consistent hardness, smooth sharpening, and dependable performance solves many everyday frustrations. And behind those pencils, a committed drawing pencil factory helps brands support their users with steady quality and stable supply.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体