Pencil slats form the backbone of any colored pencil. These wooden pieces are precisely cut to house the pigment core, providing structure and stability. Choosing the right pencil slats is important because they influence the pencil's sharpening behavior, durability, and overall feel during use. A reliable Pencil Slats factory can help maintain consistent quality for mass production, ensuring that every pencil performs as intended.

What Materials Are Typically Used in Pencil Slats?

Many pencil slats are made from softwoods like cedar, basswood, or linden. These woods are chosen for their fine grain, ease of sharpening, and minimal splintering. The wood quality directly affects the pencil's smoothness on paper and the uniformity of color application. A well-equipped Pencil Slats factory often sorts wood by density and moisture content to maintain consistency across batches.

How Pencil Slats Affect Colored Pencil Performance

The interaction between the wooden slat and the pigment core is crucial. High-quality pencil slats provide even pressure when sharpening and prevent breakage of the colored core. Slats that are too hard may cause the core to break, while overly soft wood may wear unevenly. Selecting appropriate slats can improve blending, layering, and the overall artistic experience.

Manufacturing Process of Pencil Slats

Pencil slats production involves several key steps:

- Wood Selection: Only straight-grain wood is used to prevent warping.

- Kiln Drying: Reduces moisture content to avoid cracking.

- Slat Cutting: Wood is sliced to precise thickness and width.

- Grooving: Channels are cut to hold pigment cores securely.

- Sanding and Finishing: Ensures smooth surfaces and precise dimensions.

A professional Pencil Slats factory follows these steps rigorously, which helps produce slats that meet the technical requirements of colored pencils.

Testing and Quality Control in Pencil Slats Factories

After production, pencil slats undergo inspection for uniformity, grain consistency, and straightness. Some factories also perform stress tests to verify the wood's ability to handle core insertion and sharpening without splitting. Regular quality control ensures that every pencil made with these slats provides a smooth, reliable user experience.

Customization Options from Pencil Slats Factories

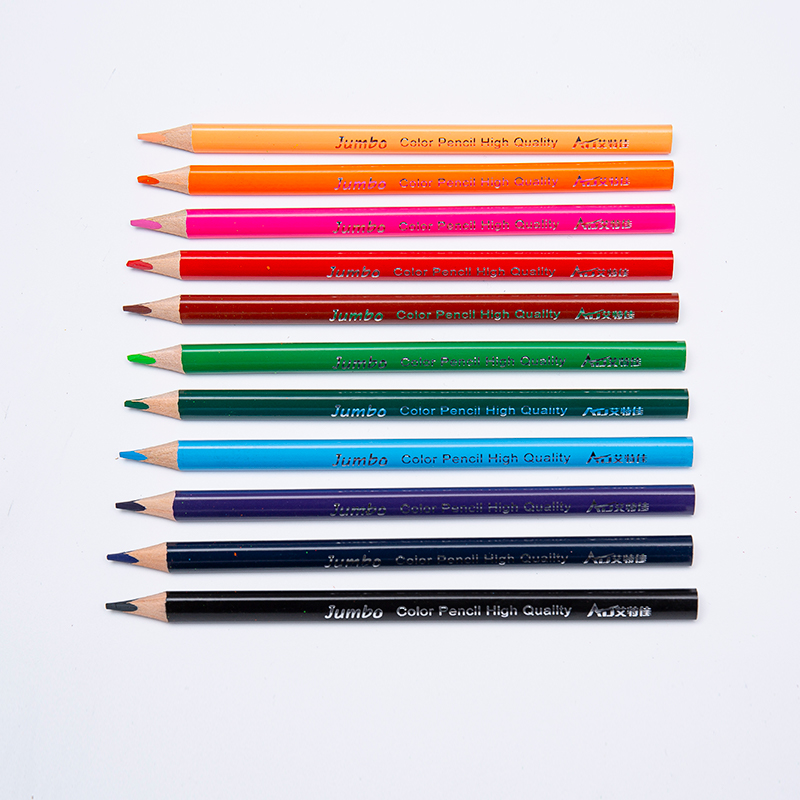

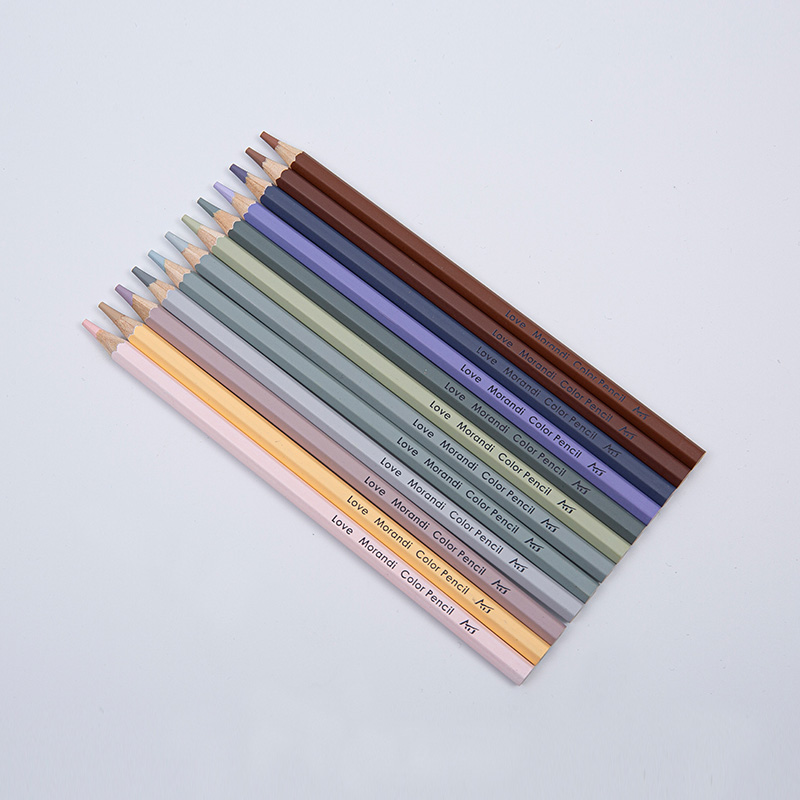

Many Pencil Slats factories offer customization services to match specific core diameters, lengths, or even wood types. This flexibility is useful for colored pencil manufacturers aiming to create unique products for different markets, including art supplies for schools, hobbyists, or professional artists.

Several elements affect the price of pencil slats: wood type, slat dimensions, production scale, and finishing requirements. Factories that maintain precise cutting, grooving, and drying processes may charge slightly more, but the investment ensures durability and better pencil performance.

Choosing the Right Pencil Slats for Your Production

When selecting a Pencil Slats factory, it's important to consider their experience with colored pencils, production capacity, and quality control standards. A factory that understands the nuances of pigment cores and wood interaction will provide slats that support the final product's consistency and usability.

Pencil slats may seem like a small component, but their quality directly impacts the performance and reliability of colored pencils. Working with an experienced Pencil Slats factory ensures that every pencil meets high standards, from smooth sharpening to consistent coloring. Understanding materials, production techniques, and factory capabilities helps manufacturers produce pencils that artists and students enjoy using.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体