Pencil slats are the foundation of every wooden pencil and play a vital role in determining the quality, durability, and overall performance of the finished product. Without well-crafted slats, even the finest graphite cores or pigments cannot perform as intended. For this reason, understanding how pencil slats are made, their standard sizes, and the way they are graded or classified is essential not only for manufacturers but also for anyone with an interest in the craft of pencil production. This guide provides a detailed overview of these important aspects.

The Production Process of Pencil Slats

The journey of a pencil slat begins with the careful selection of wood. Traditional pencil makers have long favored cedar, particularly California incense cedar, because of its fine grain, smooth texture, and natural resistance to warping. However, due to availability and cost considerations, other woods such as basswood, poplar, and jelutong are also commonly used in modern manufacturing. Each wood type brings its own characteristics—cedar is aromatic and easy to sharpen, while basswood is lightweight and cost-effective.

Once the timber is selected, it undergoes a controlled drying process to reduce moisture content. Proper drying is essential to prevent warping, cracking, or splitting during later stages of processing. After drying, the logs are sawn into thin sheets, which are then planed to achieve a uniform thickness. These sheets are cut into long strips, which are further processed into individual pencil slats.

Before slats are ready for assembly, they are often sanded and treated to ensure smooth surfaces free from rough patches, knots, or other imperfections. Some manufacturers also apply protective coatings or mild surface treatments to improve durability and ensure that slats bond well with the pencil core during gluing. The end goal is always the same: to create slats that are strong, flexible, and capable of holding the graphite or colored core securely.

Standard Sizes of Pencil Slats

Consistency in dimensions is one of the keys to efficient pencil production. Standardization ensures that machinery can operate smoothly and that finished pencils look uniform on store shelves. Typically, a pencil slat has a width of 6 to 8 millimeters and a thickness of 3 to 5 millimeters. The length of a slat usually corresponds to the standard pencil length of about 175 to 180 millimeters.

Although these are the common dimensions, manufacturers may adjust sizes slightly depending on whether they are producing standard writing pencils, larger carpenter’s pencils, or specialty art pencils. Regardless of minor variations, precision is always a top priority. Well-cut slats minimize material waste, reduce machine errors, and help ensure that the final pencils align perfectly during the gluing and shaping stages.

Grading and Classification of Pencil Slats

Not all slats are created equal. To maintain high quality, slats are graded and classified based on several criteria, including wood type, grain quality, smoothness, density, flexibility, and the presence of defects.

Grade A slats represent the quality. They feature straight grain, consistent thickness, smooth surfaces, and minimal knots or blemishes. These slats are often reserved for premium pencils where performance and appearance matter .

Grade B and Grade C slats may show slight variations in grain or minor imperfections. While not flawless, they are perfectly suitable for general writing pencils or school pencils, where affordability is more important than aesthetic perfection.

Some manufacturers also classify slats by color tone, density, or surface characteristics to match specific product designs, such as natural-wood pencils or brightly painted finishes.

This grading system allows pencil makers to allocate resources efficiently and produce pencils that consistently meet customer expectations.

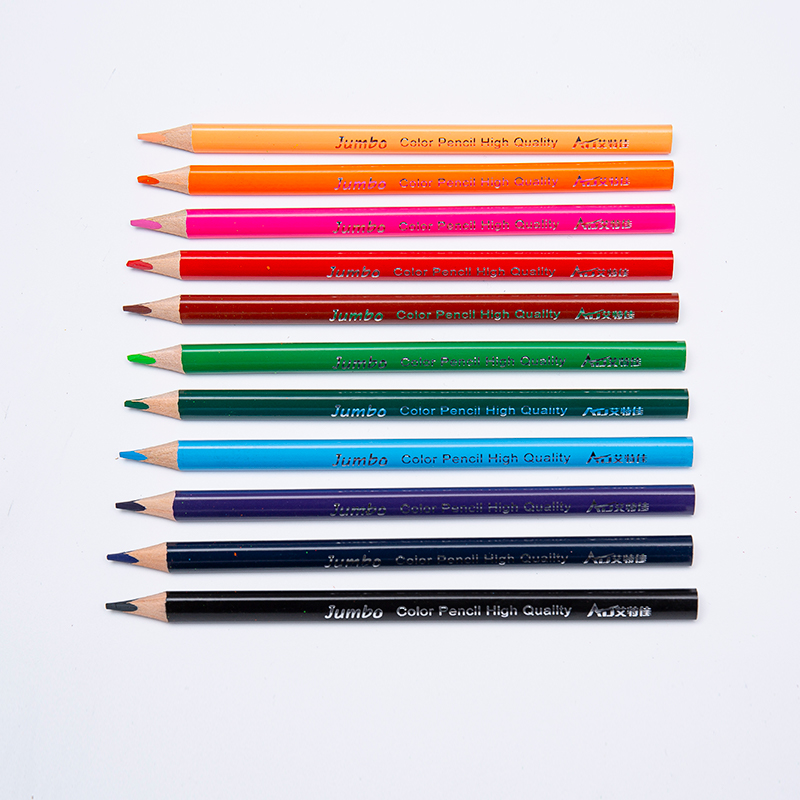

Pencil slats form the backbone of every wooden pencil, influencing both the manufacturing process and the user experience. From the careful selection and drying of wood to precise cutting, sanding, and grading, each step ensures that slats meet the high standards required for reliable pencils. Standard dimensions guarantee uniformity, while grading systems allow manufacturers to tailor products for different markets—from everyday school pencils to premium artist tools.

By understanding how pencil slats are produced, sized, and classified, manufacturers can maintain efficiency, reduce waste, and deliver pencils that are not only durable but also enjoyable to use. For stationery enthusiasts, this knowledge offers a deeper appreciation of the craftsmanship behind an object as simple, yet essential, as the wooden pencil.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体