A drawing pencil is an essential tool for artists, designers, architects, and hobbyists alike. It is not only a tool for making marks but a medium that reflects precision, technique, and creativity. Choosing the right drawing pencil can impact the quality of your sketches, technical drawings, or artistic projects. Understanding how drawing pencils are made and what differentiates one manufacturer from another can help businesses and professionals make informed decisions when sourcing these tools.

Section 1: Understanding Drawing Pencil Features

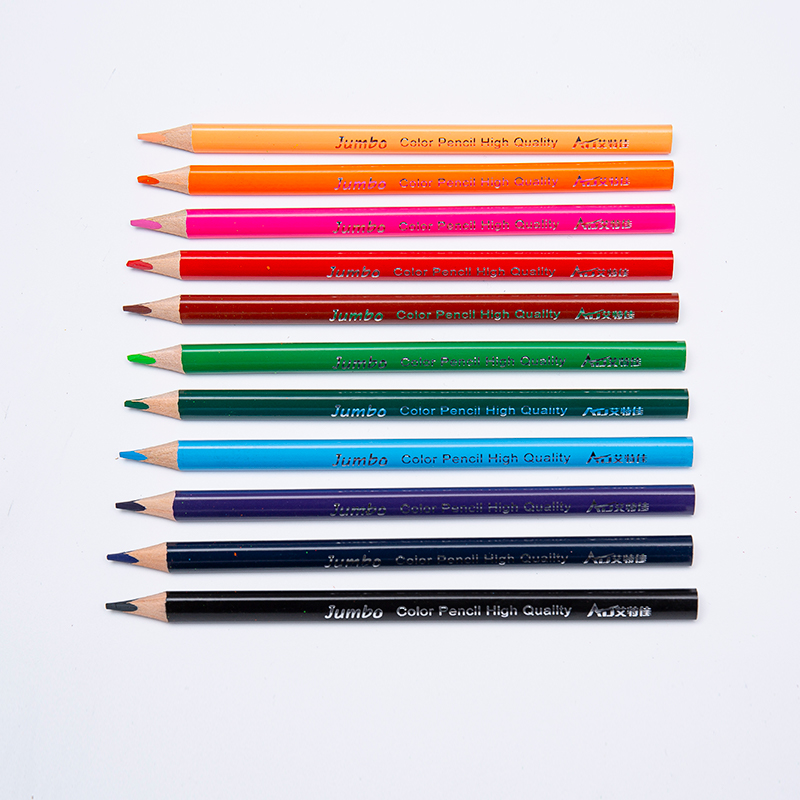

Drawing pencils come in various graphite grades, ranging from very soft (B grades) to very hard (H grades). Soft pencils produce darker, richer lines, ideal for shading and expressive sketches. Hard pencils create lighter, more precise marks, suitable for technical drawings or detailed outlines. A reliable drawing pencil manufacturer focuses on the right combination of graphite purity and wood casing to achieve smoothness, durability, and consistent line quality.

Additionally, many drawing pencils now feature eco-friendly materials or ergonomic designs to meet evolving market demands. These factors are often overlooked but can make a significant difference for bulk buyers or educational institutions looking for consistent quality across multiple units.

Section 2: Selecting the Right Drawing Pencil for Your Work

Choosing the right drawing pencil depends on both the application and user preference. For instance, architects and engineers might rely on harder pencils like H or 2H for drafting, while fine artists may use B or 2B for shading and layering. Understanding the intended use reduces waste and ensures that professionals can maintain workflow efficiency.

For B2B buyers, evaluating the consistency of pencils from a manufacturer is crucial. A single batch with inconsistent hardness can disrupt production or learning environments. This is why many companies prioritize suppliers who provide detailed specifications and quality testing reports.

Section 3: The Role of a Drawing Pencil Manufacturer

A drawing pencil manufacturer handles the entire production process—from graphite blending to shaping the wooden barrel. Precision is key: if the graphite mix is too soft or the casing poorly constructed, the pencil may break or wear unevenly. Top manufacturers invest in quality control processes to test smoothness, break resistance, and even pigmentation.

For businesses sourcing drawing pencils in bulk, understanding the manufacturer's production standards is essential. Reliable suppliers reduce returns, ensure consistent performance, and provide detailed product information that helps companies meet their operational or educational goals.

Section 4: Maintaining Drawing Pencils for Longevity

Proper maintenance of drawing pencils can extend usability and improve performance. Storing pencils in a dry environment, sharpening carefully, and avoiding drops are basic but effective practices. Manufacturers often provide pencils with protective coatings or reinforced barrels to reduce breakage.

Companies seeking suppliers may also look for manufacturers offering custom packaging or private labeling. This allows businesses to differentiate their products in competitive markets. Staying informed about industry trends ensures that buyers can choose products aligned with both user needs and sustainability expectations.

Drawing pencils remain versatile and indispensable tools for creative, educational, and professional settings. Understanding the features of each pencil grade, the manufacturer's production standards, and proper maintenance practices can help businesses and professionals select the right product. A reliable drawing pencil manufacturer provides consistent quality, ensuring that every pencil performs as expected. By considering these factors, buyers can make informed decisions that improve workflow, enhance the drawing experience, and support long-term usage.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体