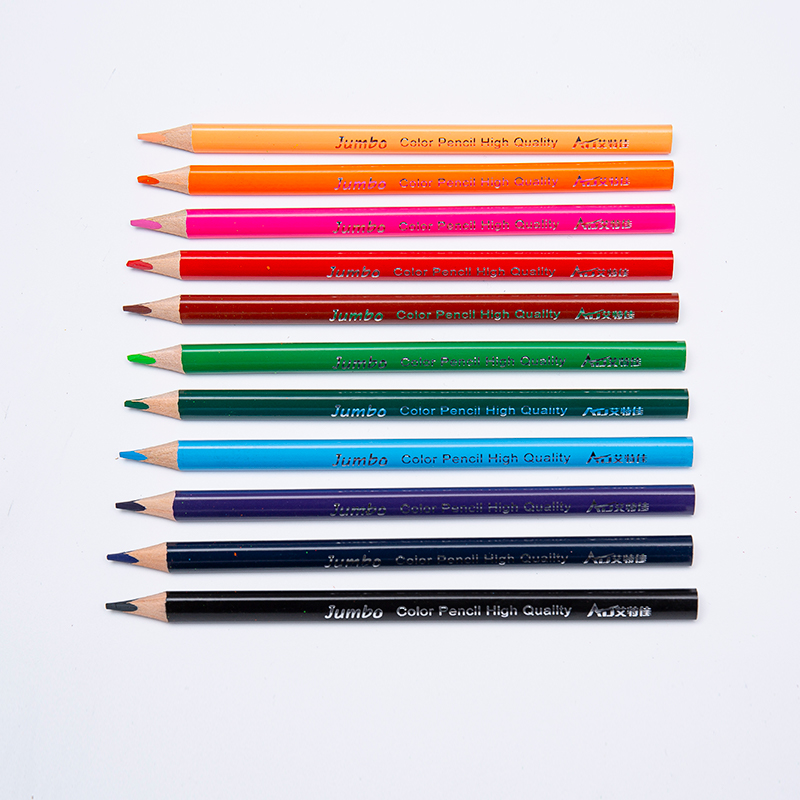

Before a pencil ever meets paper, its story begins long before in a pencil slats Factory. The smooth wooden body that feels natural in your hand doesn't start that way. It starts as raw timber, carefully processed into pencil slats - the foundation of every pencil we use for writing, sketching, or designing. Understanding how pencil slats are made reveals a blend of craftsmanship, precision, and respect for nature.

1. The Wood That Shapes the Future Pencil

The journey begins in the forest. The type of wood selected is crucial, as it determines how well a pencil can be sharpened and how comfortable it feels during use. In a pencil slats Factory, popular choices often include softwoods like cedar or basswood because they are smooth, easy to cut, and have a pleasant texture.

After being cut into logs, the wood is seasoned and dried to reduce moisture. This step is important because stable wood prevents warping or cracking during later production stages. The dried wood is then cut into thin rectangular sheets - the pencil slats. Each slat must have consistent grain and density, allowing the graphite core to be placed well inside later on.

2. Precision in Every Step

Inside a modern pencil slats Factory, the production process combines both technology and skill. The slats are inspected for uniform thickness, straight edges, and natural wood balance. Even the smallest variations can affect the final pencil's quality and comfort.

At this stage, grooves are milled into each slat where the graphite or color core will sit. Another slat is glued on top, forming what will eventually become the pencil's body. Before this step, however, factories make sure the slats bond smoothly and evenly, without gaps. The accuracy of this step decides whether the pencil will sharpen neatly or break unevenly.

After shaping and gluing, the wood is pressed and left to dry again, creating a solid sandwich ready for cutting into individual pencils. The whole process might look simple, but achieving balance between hardness, flexibility, and texture takes years of experience and attention to detail.

3. Why Pencil Slats Matter More Than You Think

For many people, a pencil feels like a basic everyday item. Yet without the right pencil slats, even the finest graphite core wouldn't perform properly. Good slats allow a pencil to sharpen smoothly and protect the inner core from breaking. They also influence how the pencil feels - whether it's lightweight, smooth, or textured in your hand.

Factories constantly test new materials and coatings to improve durability and reduce waste. Some have started using sustainably sourced wood or alternative, eco-friendly materials, showing that even a simple pencil can adapt to modern environmental values.

4. The Quiet Craft Behind Every Pencil

What's fascinating about visiting a pencil slats Factory is seeing how tradition meets progress. You'll find experienced workers checking wood grain by hand while automated machines cut and shape with millimeter precision. Each step reflects the effort to create something both functional and beautiful.

When you hold a pencil, you're holding the result of many quiet steps - from tree selection to precise shaping of pencil slats. Every curve and line in your sketch begins with this unseen foundation. It's a reminder that even the simplest tools in our daily lives have an entire world of craftsmanship behind them.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体