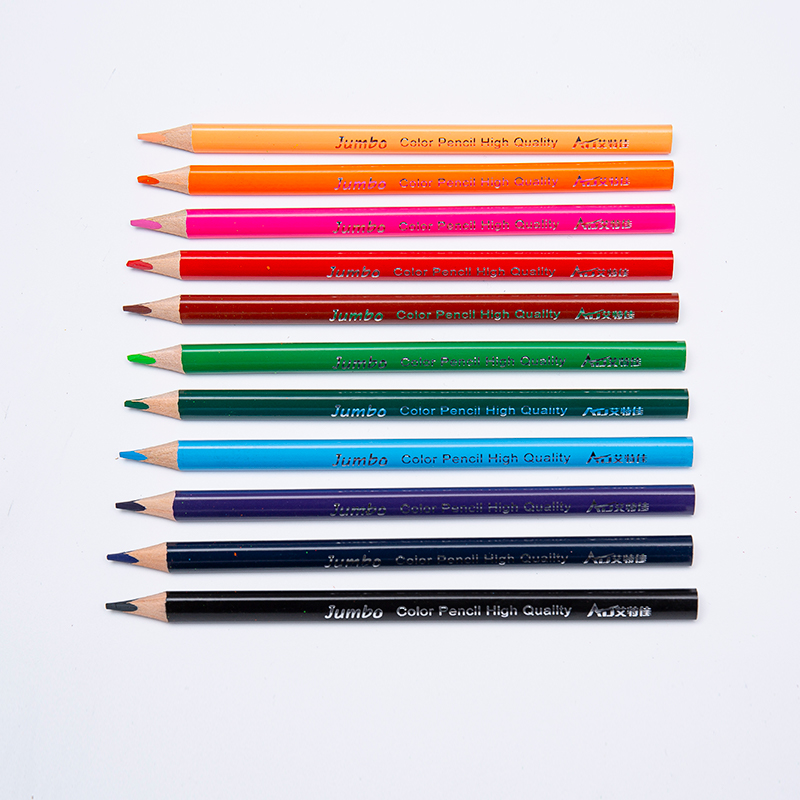

If you're an artist, you know the feeling. The smooth glide of a pigment-rich core onto paper, the ability to layer colors without waxy buildup, and the sharp point that holds its edge through intricate details. We often attribute these qualities to the pigment or the binder formula. But what if the true unsung hero of your artistic experience is a component you never see: the color pencil lead die.

The Heart of the Matter: What is a color pencil lead die?

Before we can understand its impact, let's clarify what we're discussing. A color pencil lead is not a part of the pencil itself. It is a precision tool, typically a small metal plate with specifically sized and shaped holes. During production, the soft, pliable mixture of pigment, clay, and binder is forced, or extruded, through these holes under significant pressure. This process forms the wire into continuous, uniform strands, which are then cut, dried, and baked to become pencil lead. The relationship between a brand and its color pencil lead Die Manufacturer is therefore a foundational one. The capabilities and expertise of the color pencil lead Die Manufacturer directly influence the potential of the pencils they help create.

From Shape to Stroke: The Die's Direct Impact

1. Consistency and Strength

A primary function of the color pencil lead Die is to create a cause that is consistent in diameter from end to end. Any variation can cause a feel uneven in the hand, applies color inconsistently, or is prone to breaking. A high-precision color pencil lead ensures that every millimeter of the core has the same density and composition. This uniformity is what gives a pencil its reliable strength, allowing you to apply pressure for dark shades without fearing a snap. The engineering standards upheld by a skilled color pencil lead Die Manufacturer are what prevent the frustrating experience of a broken core mid-stroke.

2. Vibrancy and Layering

This is where the connection becomes particularly interesting for artists. The surface texture of the lead, which is a direct result of the color pencil lead's interior finish, plays a significant role in how pigment is released. A finely smooth hole in the color pencil lead Die will produce a cause with a very hard, almost glossy surface. This can feel slippery on paper and may not deposit pigment as readily. Conversely, a die engineered with a specific micro-texture can create a cause that has a slightly more porous, "toothy" surface. This texture grips the paper fibers better, allowing for a more immediate and generous transfer of pigment. This results in richer, more vibrant color with less effort. This pigment release is what makes complex layering techniques possible. The layer adheres effectively without filling the tooth of the paper, allowing subsequent layers to build up smoothly for deep, luminous effects.

3. Point Retention and Sharpening

The density and homogeneity achieved by a color pencil lead also determine how well a pencil can be sharpened and how long it holds a point. A cause that is extruded with inconsistencies might have soft spots that crumble during sharpening or hard spots that cause the point to break. The collaboration between a pencil company and its color pencil lead Die Manufacturer is essential for achieving this balance between softness for pigment release and strength for point integrity.

While the brilliance of a color pencil begins with its pigments, its soul is shaped by the color pencil lead Die. This small but critical tool defines the physical character of the lead, influencing everything from its basic strength to its complex interaction with paper. The next time you appreciate the smooth, vibrant flow of color from your love pencil, remember the unseen precision of the color pencil lead Die and the specialized color pencil lead Die Manufacturer that helped make that moment possible.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体