The pencil is one of the widely used writing instruments in the world, and behind its simple appearance lies a precise manufacturing process. At the center of this process are pencil slats, which form the wooden body that holds the graphite or colored core. To understand why these components are so important, it is useful to look at what pencil slats are, the materials typically used, and their significance in pencil production.

What Are Pencil Slats?

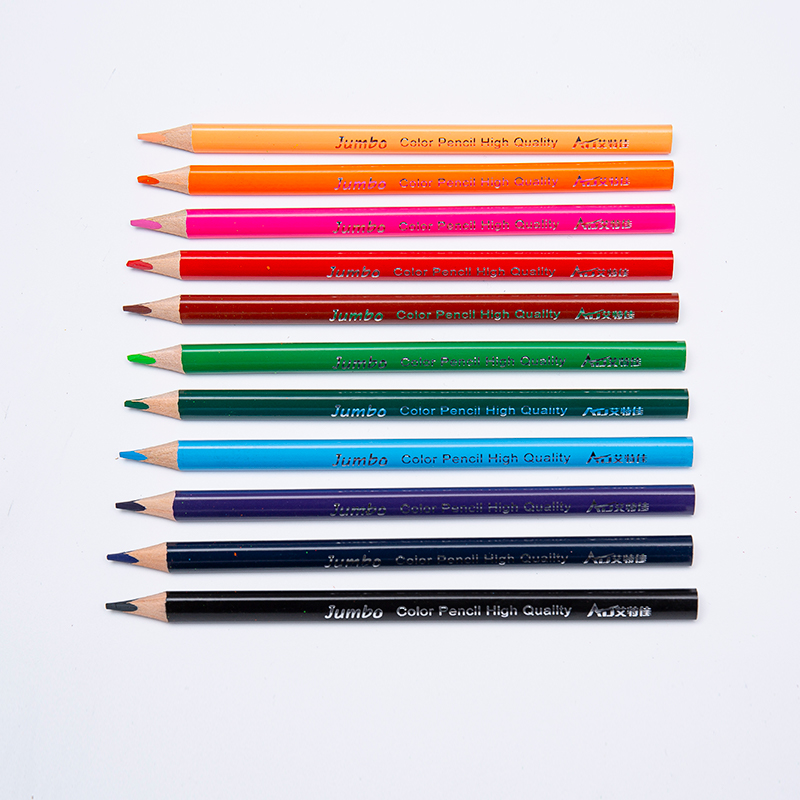

Pencil slats are thin, rectangular pieces of wood prepared specifically for the production of pencils. They serve as the base material from which the pencil body is shaped. Each slat is cut to a uniform thickness, length, and width so that it can be efficiently processed in automated machinery. Grooves are milled into the slats to hold the graphite or color leads, after which two slats are glued together to form a sandwich enclosing the core. Once bonded, the slats are cut into individual pencils and shaped into the familiar round, hexagonal, or triangular profiles.

Without well-prepared pencil slats, it would be difficult to achieve the smooth surfaces, reliable bonding, and consistent quality that modern pencils require. Their uniformity directly impacts the performance and durability of the final writing instrument.

Which Types of Wood Are Commonly Used for Pencil Slats?

The choice of wood is a key factor in the quality of pencil slats. Traditionally, incense cedar has been regarded as the premium wood for pencil manufacturing. It is valued for its straight grain, softness, and ability to sharpen easily without splintering. However, due to cost and resource availability, other types of wood are also widely used.

Basswood is one of the common alternatives, offering a good balance of affordability and workable properties. Jelutong, poplar, and other regionally available species are also employed, depending on where the pencil slats are produced. Manufacturers select wood that can be cut smoothly, resists warping, and provides a reliable surface for painting or finishing.

Modern developments have also led to the use of reconstituted or engineered wood materials for pencil slats, especially in areas where natural resources are limited. These alternatives aim to maintain consistent quality while promoting sustainable use of raw materials.

Why Are Pencil Slats Important in Pencil Manufacturing?

The importance of pencil slats lies in their role as the structural backbone of the pencil. A good slat ensures that the pencil is easy to sharpen, comfortable to hold, and durable during everyday use. Poor-quality slats, on the other hand, may cause breakage, rough sharpening, or irregular surfaces that reduce user satisfaction.

In large-scale manufacturing, uniform pencil slats are essential for efficiency. Machines that cut grooves, insert leads, and shape the pencils rely on precise dimensions. Even small variations in slat thickness or grain consistency can disrupt production and affect quality. This prepares slats a highly controlled process, often involving drying, cutting, and surface treatment before they reach the assembly stage.

Sustainability is another reason why pencil slats are carefully selected. Many manufacturers work with certified suppliers to ensure that wood used in slats comes from responsibly managed forests. This not only preserves resources but also aligns with growing global expectations for environmentally responsible production.

Pencil slats may appear simple, but they are a crucial part of pencil manufacturing. They provide the structure that holds the writing core, influence how easily a pencil sharpens, and determine much of the overall quality of the finished product. The choice of wood, whether cedar, basswood, or engineered materials, plays a significant role in shaping performance and sustainability. For both manufacturers and users, understanding the role of pencil slats highlights the importance of material selection and precision in creating an everyday tool that has been relied upon for centuries.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体