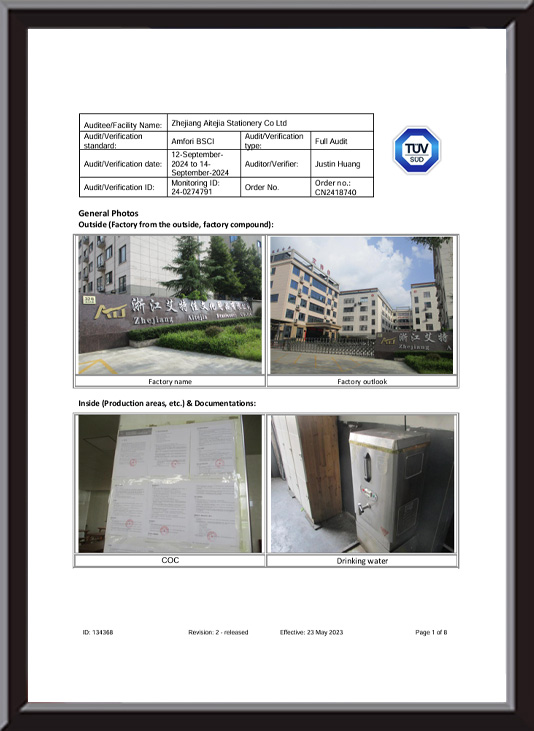

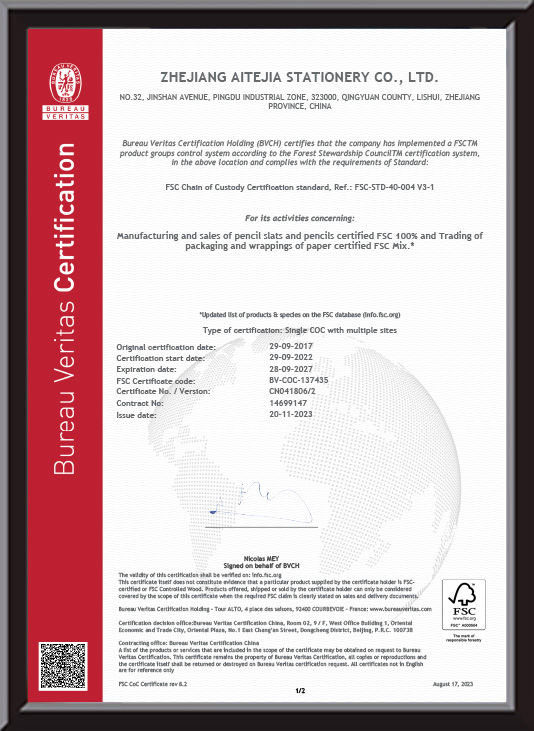

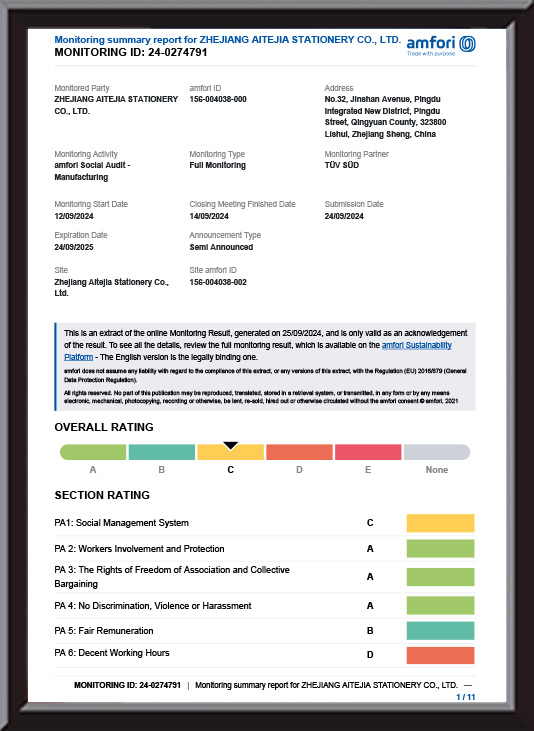

Founded in 2004 and located at 32 Jinshan Avenue, Pingdu Industrial Zone, Qingyuan County, Zhejiang Province, Zhejiang Aitejia Stationery Co., Ltd. is a company that integrates research and development, production and sales. We specialize in pencil production, offering more than 30 product types with complete specifications and an annual production capacity of more than 900 million pencils. With deep R&D strength, reliable products, extensive sales network, and sound corporate management, our company provides a one-stop writing solution for customers worldwide.

-

Founded in

0

Years

-

Variety Type

0+

Number

-

Production Capacity

0+

Million

We will continue to pursue quality with high standards and a rigorous attitude, and provide reliable products and services to our customers.

View More-

01 Stable Product QualityThe company strictly implements procedures such as screening and auditing of raw material suppliers, testing of incoming materials, and comparison of incoming materials; each batch of products is more stable and traceable, achieving high-efficiency production control.

-

02 Customization CapabilitiesBy offering comprehensive ODM and OEM services, we allow our customers to customize pencil shapes to their specific needs and brand requirements. Our company aims to provide a seamless collaborative experience, allowing customers to realize their unique product concepts while maintaining high quality and brand integrity.

-

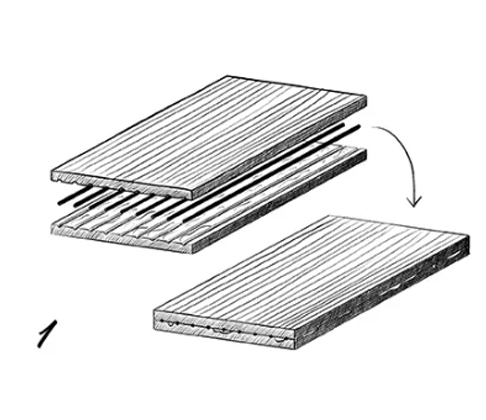

GlueGrooves are precision-cut into wood slats. Two slats are then glued together in a sandwich formation with graphite cores positioned in between.

GlueGrooves are precision-cut into wood slats. Two slats are then glued together in a sandwich formation with graphite cores positioned in between. -

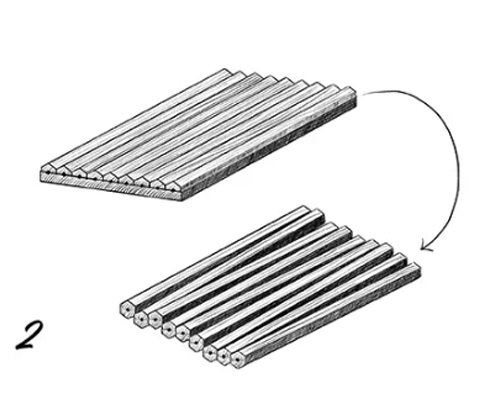

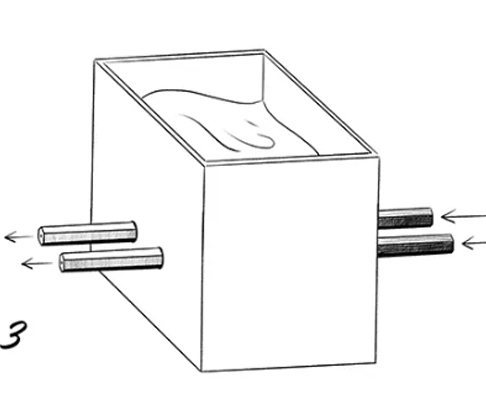

ShapingAfter drying, the assembled slats are shaped sequentially on each side. This process produces unfinished wood-cased pencils ready for finishing.

ShapingAfter drying, the assembled slats are shaped sequentially on each side. This process produces unfinished wood-cased pencils ready for finishing. -

PaintThe pencils receive multiple thin coats of paint or varnish (up to seven applications) to create a smooth, even finish. For special editions, foil wrapping may be applied instead.

PaintThe pencils receive multiple thin coats of paint or varnish (up to seven applications) to create a smooth, even finish. For special editions, foil wrapping may be applied instead. -

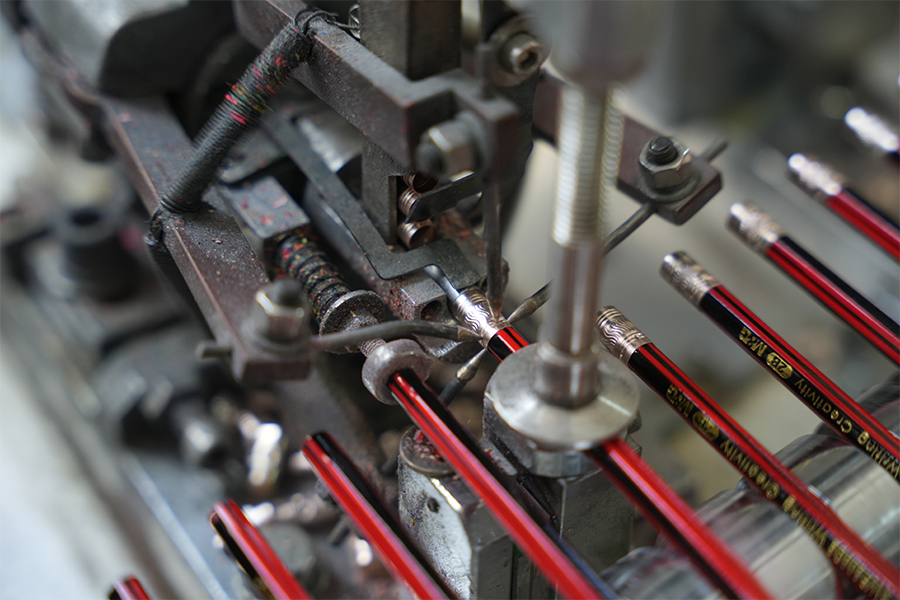

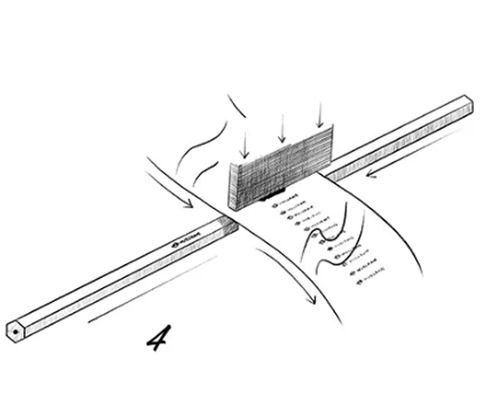

ImprintingDesigns are applied using a hot foil stamping machine equipped with custom metal dies.

ImprintingDesigns are applied using a hot foil stamping machine equipped with custom metal dies. -

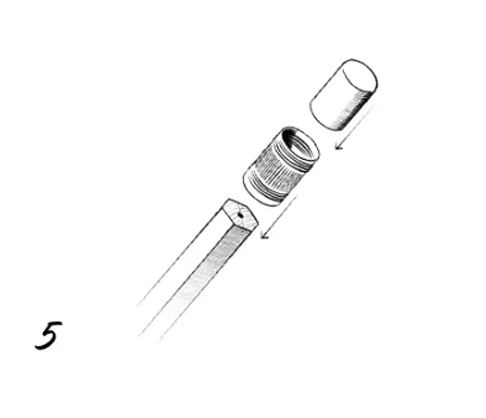

TippingEach pencil receives a ferrule (the metal sleeve) and eraser, which are securely clamped onto the end.

TippingEach pencil receives a ferrule (the metal sleeve) and eraser, which are securely clamped onto the end. -

Quality ControlThroughout production, pencils undergo rigorous quality inspections. Defective units are removed from the line. Approved pencils are then carefully packaged for shipment to customers.

Quality ControlThroughout production, pencils undergo rigorous quality inspections. Defective units are removed from the line. Approved pencils are then carefully packaged for shipment to customers.

English

English  Français

Français عربى

عربى Español

Español 中文简体

中文简体